Stop the Drip: Identify, Understand, and Fix Fluid Leaks Fast

Spotting the Signs Before the Drips Add Up

Under the Hood: Fluids Every Driver Should Recognize

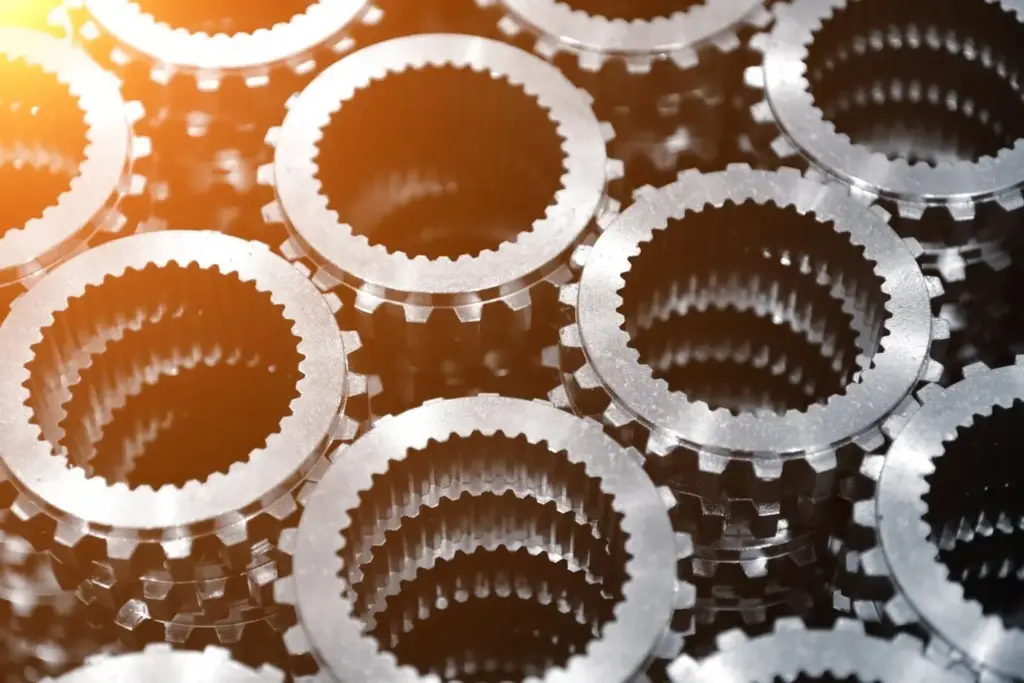

Likely Culprits: Gaskets, Hoses, Seals, and Fittings

Heat, Pressure, and Age

Every start, drive, and shutdown expands and contracts gaskets and hoses. Over years, elastomers lose plasticizers, becoming brittle and less compliant. Pressure spikes from stuck thermostats or restricted coolers exploit those weaknesses, creating pinholes and weeping seams. Oil additives also deplete, shrinking seals. The best defense is timely replacement by mileage or condition, plus ensuring heat shields, splash guards, and mounts are intact so components aren’t forced to flex in ways they were never designed.

Installation Errors and Overtightening

A wrench can heal or harm. Overtightening pan bolts bows flanges, creating uneven gasket compression and paths for leaks. Under‑torque invites seepage, while skipping cross‑pattern torque sequences twists covers. Dirty mating surfaces, leftover RTV, and nicks around bolt holes prevent seals from seating. Use torque specs, clean with lint‑free towels, chase threads, and let gasket makers cure as directed. A few careful minutes during installation often saves hours of chasing drips and second attempts later.

Contamination and Incorrect Fluids

Mixing coolants, using the wrong ATF, or topping brake systems with incompatible fluids accelerates seal breakdown and internal corrosion. Even shop towels with the wrong solvents can swell rubber. Dirt introduced during funnel use grinds into mating surfaces and pump vanes. Label bottles, use dedicated funnels, and keep caps clean. If a mystery top‑off happened, consider a full flush rather than piecemeal correction. Compatibility charts from automakers and fluid suppliers are invaluable, and worth bookmarking now.

Quick Fixes You Can Safely Do Today

Temporary Stopgaps That Actually Help

Gently snug a loose hose clamp, replace a cracked worm‑drive with a quality constant‑tension style, and clean mating lips before reseating. Add fresh crush washers to banjo fittings. For coolant, a trimmed section of new hose and proper clamps beat magic powders. Use thread sealant on low‑pressure fittings if specified by manuals. Wipe surfaces dry, then recheck after a short drive. Temporary means temporary: schedule a proper replacement once you confirm the source under clean conditions.

Safe Clean-Up and Environmental Care

Contain first, then clean. Slide absorbent pads under the drip, and ring the area with kitty litter to prevent spreading. Never hose oily residue into storm drains. Bag contaminated materials separately and follow local disposal rules. Degrease cautiously, keeping chemicals off belts and electrical connectors. Photograph before and after so you can verify progress. A tidy work area not only respects the environment; it also reveals fresh leak paths faster and keeps your hands, gloves, and tools safer.

Red Flags That Require a Professional

Some symptoms mean stop driving now: rapidly dropping brake fluid, milky oil suggesting coolant contamination, ATF pouring near the bellhousing, or fuel smell strong enough to sting. Power steering hoses sweating lightly are one thing; streams near exhaust are another. When dashboard warnings light, or the leak accelerates with revs, call a tow. Pros have pressure testers, smoke machines, and dye kits to isolate issues precisely, protecting expensive components and ensuring your repair dollars land where needed.

Tools, Materials, and Readiness

Stories from the Road and Driveway